Macro Cut Object For Magnets/fr

| Description |

|---|

| Découpe un objet suivant un plan et ajoute des trous alignés pour aimants avec détection de collision de surface. Crée deux pièces avec des trous parfaitement alignés pour y insérer des aimants qui permettent aux pièces de s'emboîter. Version macro : 0.6.2 Date dernière modification : 2026-01-18 Version FreeCAD : 0.21+ Téléchargement : Icône de la barre d'outils Auteur: Spkane |

| Auteur |

| Spkane |

| Téléchargement |

| Icône de la barre d'outils |

| Liens |

| Page des macros Comment installer une macro Comment créer une barre d'outils |

| Version Macro |

| 0.6.2 |

| Dernière modification |

| 2026-01-18 |

| Version(s) FreeCAD |

| 0.21+ |

| Raccourci clavier |

| None |

| Voir aussi |

| Part Séparer en composés, PartDesign Perçage |

Description

Cette macro découpe un objet 3D selon un plan spécifié et ajoute automatiquement des trous magnétiques alignés aux deux pièces obtenues. Les trous sont positionnés à l'aide d'une détection de collision intelligente afin de garantir qu'ils ne traversent pas les parois extérieures de l'objet.

Cela est particulièrement utile pour :

- Créer des impressions en plusieurs parties qui s'assemblent à l'aide d'aimants intégrés.

- Diviser des objets volumineux pour les adapter à des plateaux d'imprimantes 3D plus petits tout en conservant leur alignement.

- Ajouter des mécanismes de fermeture magnétiques à des boîtiers et des étuis.

Principales fonctions :

- Découpe suivant des plans prédéfinis (XY, XZ, YZ) ou des plans de référence du modèle.

- Placement automatique des trous avec une répartition uniforme le long du bord de coupe.

- La détection des collisions de surface empêche les trous de traverser les parois.

- Diamètre, profondeur et nombre de trous configurables.

- Paramètres de dégagement préféré et minimum des bords.

- Repositionnement intelligent des trous lorsque le placement initial ne satisfait pas aux contrôles de sécurité.

- Crée des objets PartDesign::Body avec des fonctions de trou paramétriques.

- Prend en charge la recoupe d'objets déjà coupés (conserve les trous existants).

- Sépare automatiquement les deux parties pour faciliter la visualisation.

Utilisation

- Ouvrez un document contenant l'objet que vous souhaitez découper.

- Vous pouvez sélectionner l'objet et/ou un plan de référence avant d'exécuter la macro.

- Exécutez la macro à partir de Macro → Macros → CutObjectForMagnets → Lancer.

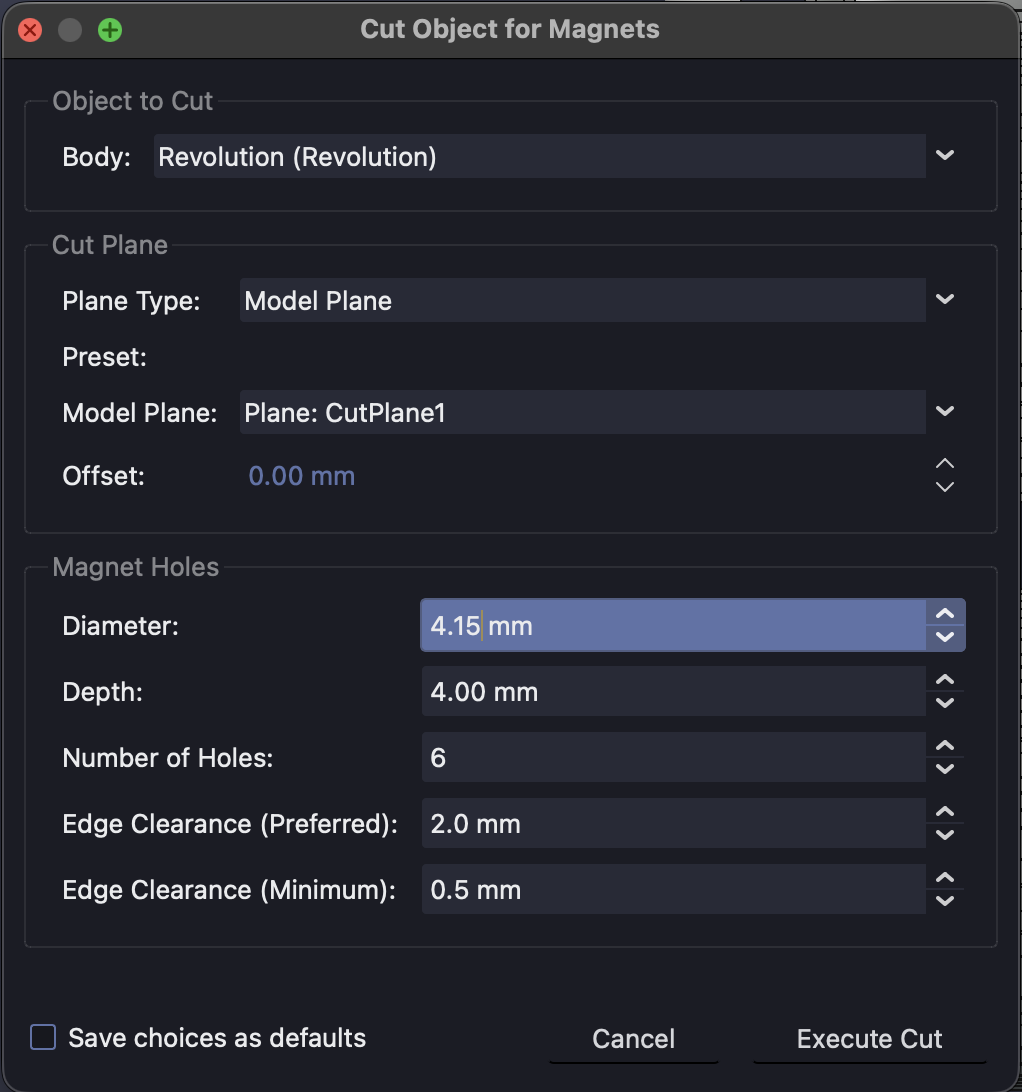

- Dans la boîte de dialogue :

- Sélectionnez le corps à découper dans le menu déroulant.

- Choisissez le type de plan de découpe (Préréglé ou Plan du modèle).

- Pour les plans prédéfinis, définissez le décalage par rapport à l'origine.

- Configurez les paramètres des trous pour aimants :

- Diameter : diamètre du trou (doit correspondre à la taille de votre aimant).

- Depth : profondeur du trou à partir de la surface de découpe.

- Number of Holes : nombre total de trous à créer.

- Edge Clearance (Preferred) : distance idéale entre l'arrête du trou et la surface de l'objet.

- Edge Clearance (Minimum) : dégagement minimum acceptable.

- Cliquez sur « Execute Cut ».

Exemple

Cette image montre un vase dans sa forme originale, puis après avoir été découpé plusieurs fois à l'aide de la macro. Des aimants peuvent ensuite être insérés dans l'objet, qui peut alors être réassemblé. Cet exemple visait à créer un vase « cassable » pour une représentation théâtrale, mais il existe de nombreuses autres utilisations potentielles.

Fonctionnement

Processus de découpe :

- Crée une grande boîte demi-espace alignée avec le plan de découpe.

- Utilise des opérations booléennes pour diviser l'objet en deux parties.

- Crée des conteneurs PartDesign::Body pour chaque moitié.

Algorithme de placement des trous :

- Calcule les positions des trous répartis uniformément le long du périmètre de la face coupée.

- Pour chaque position, valide les DEUX pièces (et pas seulement une).

- Utilise d'abord le dégagement préféré, puis revient au minimum si nécessaire.

- Vérifie l'espacement entre les trous (minimum 2 fois le diamètre).

- Repositionne les trous qui ne satisfont pas aux contrôles de sécurité à l'aide de plusieurs stratégies :

- Réduction du dégagement à la même position.

- Augmentation de l'encastrement par rapport au bord.

- Positions alternatives le long du périmètre.

Fonctions de sécurité :

- Crée des cylindres de test pour vérifier si les trous risquent de traverser les murs.

- Vérifie chaque trou par rapport aux parties supérieure et inférieure.

- Ignore les trous qui ne peuvent pas être placés en toute sécurité.

- Signale les trous repositionnés et ignorés dans la console.

Paramètres

| Paramètre | Description | Valeur par défaut |

|---|---|---|

| Plane Type | « Plan prédéfini » (XY/XZ/YZ) ou « Plan du modèle » (plan de référence) | Plan prédéfini |

| Offset | Distance par rapport à l'origine pour les plans prédéfinis | 0 mm |

| Diameter | Diamètre du trou pour l'aimant | 3 mm |

| Depth | Profondeur du trou par rapport à la surface de coupe | 3 mm |

| Number of Holes | Nombre total de trous à créer | 6 |

| Edge Clearance (Preferred) | Distance idéale entre le bord du trou et la surface de l'objet | 2 mm |

| Edge Clearance (Minimum) | Dégagement minimum acceptable (utilisé lors du repositionnement) | 0.5 mm |

Conditions

- FreeCAD 0.19 ou version ultérieure.

- Un objet avec une forme solide (corps Part ou PartDesign).

- Pour le mode modèle réduit d'avion : un plan de référence ou un objet avec des faces planes.

Installation

- Installez via le gestionnaire d'extensions FreeCAD ou manuellement à partir du dépôt freecad-macro-cut-for-magnets sur GitHub.

Astuces

- Magnet sizing : mesurez soigneusement vos aimants. Les dimensions courantes sont 3 mm, 5 mm et 6 mm de diamètre.

- Add tolerance : pensez à ajouter 0,1 à 0,2 mm au diamètre pour faciliter l'insertion des aimants.

- Depth planning : réglez la profondeur du trou légèrement plus profonde que la hauteur de l'aimant pour garantir un ajustement affleurant ou encastré.

- Edge clearance : pour les objets à parois minces, réduisez le dégagement souhaité, mais conservez un dégagement minimum suffisamment important pour éviter de percer la paroi.

- Re-cutting : la macro détecte les trous d'aimants existants et les préserve lors de la découpe de pièces déjà découpées.

Code source

Le code source complet est hébergé sur GitHub : freecad-macro-cut-for-magnets sur GitHub

Liens

- Documentation complète : guides et tutoriels complets.

- Dépôt sur GitHub : code source et suivi des problèmes.

- Part Séparer en composés : outil de découpage intégré à FreeCAD.

- PartDesign Perçage : documentation sur les fonctions paramétriques de perçage.

- PartDesign Corps : documentation sur les conteneurs de corps.