SheetMetal AddWall

This documentation is not finished. Please help and contribute documentation.

GuiCommand model explains how commands should be documented. Browse Category:UnfinishedDocu to see more incomplete pages like this one. See Category:Command Reference for all commands.

See WikiPages to learn about editing the wiki pages, and go to Help FreeCAD to learn about other ways in which you can contribute.

|

|

| Menu location |

|---|

| SheetMetal → Make Wall |

| Workbenches |

| SheetMetal |

| Default shortcut |

| W |

| Introduced in version |

| - |

| See also |

| None |

Description

The SheetMetal AddWall command creates flanges on selected edges. By changing the Dataangle property a flange it can be turned into a hem.

A flange usually consists of a 90° cylindrical bend and a planar strip (wall).

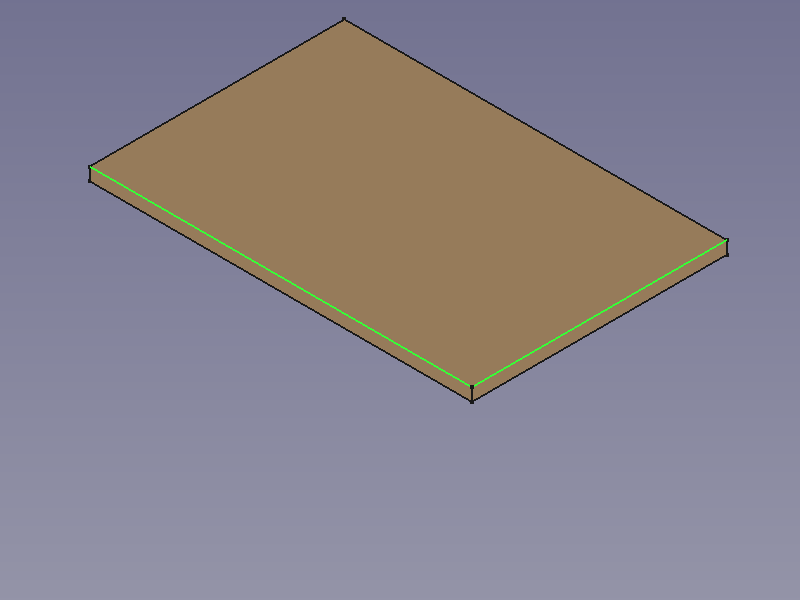

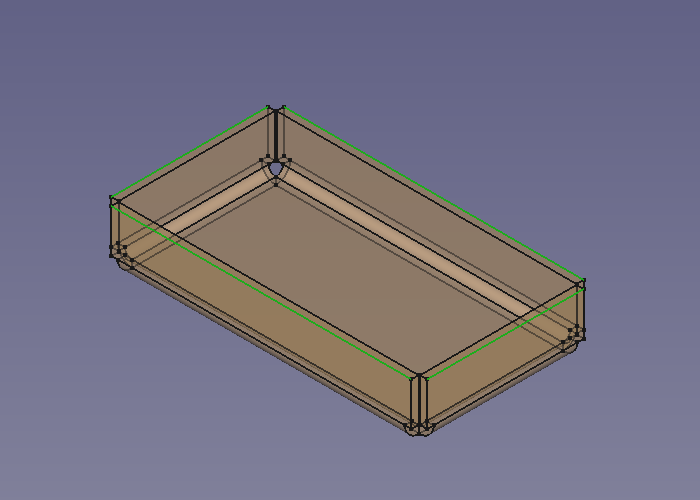

Two selected edges → two flanges

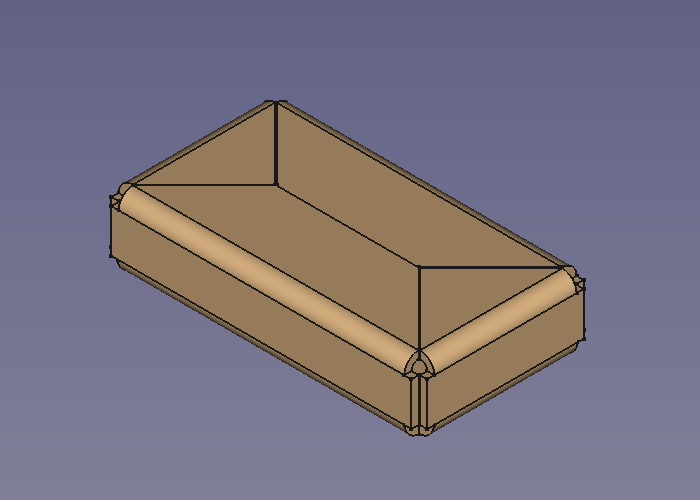

It is called a hem instead if the bend is roughly 180°.

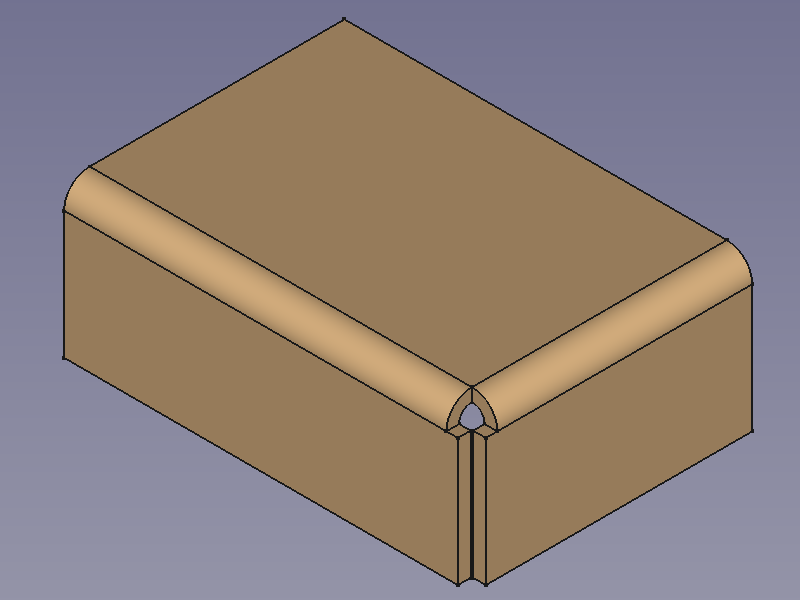

Two selected edges → two mitered hems

Usage

- Select one or more edges of a solid shape.

- There are several ways to invoke the command:

- A Bend object is created that consists of one new flange at each selected edge, and the Flange properties Task Panel opens:

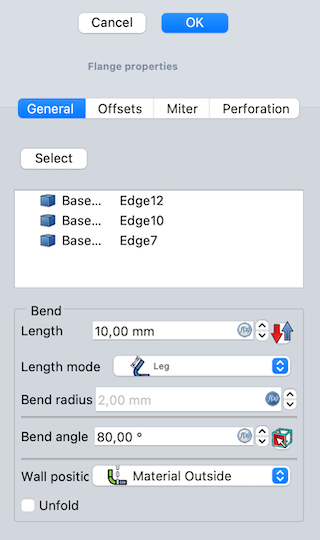

- With the General tab selected:

- Optionally press the Select button to add more edges.

- Optionally press the Clear selection button to clear the list of selected edges (introduced in 0.7.11).

- Press the Preview button to finish the selection and display the changes.

- Optionally adjust the bend parameters in this tab. See the General section of the Task Panel description below

- Optionally press the Select button to add more edges.

- Optionally switch to another tab to adjust more parameters. See Offsets, Miter, or Perforation section of the Task Panel description below.

- With the General tab selected:

- Press the OK button to finish the command and close the Task Panel.

- Optionally adjust the parameters in the Property View.

Task Panel

A Task Panel with four tabs was introduced in 0.6.00

Double-click an existing Bend object in the Tree View to re-open the Task Panel and edit the parameters.

General

- Select: Changes the amount of edges in the base Object property.

- Length: Sets the length property.

Reverse the wall: Toggles the invert property.

- Length mode: Sets the Length Spec property.

- Bend radius: Sets the radius property.

- Bend angle: Sets the angle property.

Face reference: Switches the Bend angle option to read-only mode and displays two further options:

- Reference: Awaits a face to be selected in the 3D View and links it to the Angle Face Reference property.

- Relative angle: Sets the Relative Angle To Ref property.

- Wall position: Sets the Bend Type property.

- If set to

Offsettwo further options are available:

- Offset: Sets the offset property.

Face reference: Switches the Offset option to read-only mode and displays two further options:

- Reference: Awaits a face to be selected in the 3D View and links it to the Offset Face Reference property.

- Offset position: Sets the Offset Type property.

- If set to

Offsetanother option is available:

- Offset from reference: Sets the Offset Type Offset property.

- If set to

- If set to

- Unfold: Toggles the unfold property.

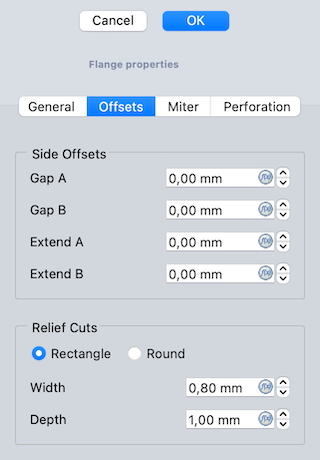

Offsets

- Gap A: Sets the gap1 property.

- Gap B: Sets the gap2 property.

- Extend A: Sets the extend1 property.

- Extend B: Toggles the extend2 property.

- Rectangle and Round radio buttons: Toggle relief Type property.

- Width: Sets the reliefw property.

- Depth: Toggles the reliefd property.

Miter

- Auto Miter: Toggles the Auto Miter property.

- If checked:

- Minimum Gap: Sets the minGap property.

- Max Extend Distance: Sets the max Extend Dist property.

- If unchecked:

- Angle 1: sets the miterangle1 property.

- Angle 2: sets the miterangle2 property.

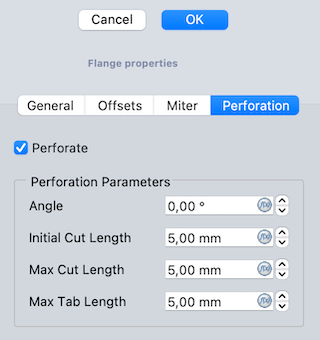

Perforation

- Perforate: Toggles the Perforate property.

- If checked:

- Angle: Sets the Perforation Angle property.

- Initial Cut Length: Sets the Perforation Initial Length property.

- Max Cut Length: Sets the Perforation Max Length property.

- Max Tab Length: Sets the Nonperforation Max Length property.

Notes

- See Create a sheet metal object for a basic workflow.

Properties

See also: Property View.

A SheetMetal Bend object is derived from a Part Feature object or, if it is inside a PartDesign Body, from a PartDesign Feature object, and inherits all its properties. It also has the following additional properties:

Data

Parameters

- DataBend Type (

Enumeration): "Bend Type".Material Outside(default),Material Inside,Thickness Outside,Offset. - DataLength Spec (

Enumeration): "Type of Length Specification".Leg(default),Outer Sharp,Inner Sharp,Tangential. - Dataangle (

Angle): "Bend Angle". Default angle:90,00°. - Database Object (

LinkSub): "Base Object". Link to the planar face to receive a bend. - Dataextend1 (

Distance): "Extend from Left Side". Default:0,00 mm. - Dataextend2 (

Distance): "Extend from Right Side". Default:0,00 mm. - Datagap1 (

Distance): "Gap from Left side". Default:0,00 mm. - Datagap2 (

Distance): "Gap from Right side". Default:0,00 mm. - Datainvert (

Bool): "Invert Bend Direction". Default:false. - Datalength (

Length): "Length of Wall". Default:10,00 mm. - Dataradius (

Length): "Bend Radius", the default value depends on the radius property of the parent feature:- That property is not existent: This property is set to

1,00 mm. - That property contains a numeric value: An expression linking that property is inserted into this property.

- That property contains an expression: The expression is copied into this property.

- That property is not existent: This property is set to

Parameters Ex

- DataAngle Face Ref Mode (

Bool): "Enable face reference for angle". Default:true. introduced in 0.7.11 and removed before 0.7.58 - DataAngle Face Referene (

LinkSub): "Face reference for angle". Default:true. introduced in 0.7.11 - DataAuto Miter (

Bool): "Enable Auto Miter". Default:true. - DataOffset Face Ref Mode (

Bool): "Enable face reference for offset". Default:true. introduced in 0.7.11 and removed before 0.7.58 - Data Offset Face Reference (

LinkSub): "Face reference for offset". Default:true. introduced in 0.7.11 - DataOffset Type (

Enumeration): "Offset Type". introduced in 0.7.11- Values:

Material Outside,Material Inside(default),Thickness Outside,Offset.

- Values:

- DataOffset Type Offset (

Distance): "Works when offset face reference is on. It offsets by a normal distance from the offset reference face". Default:0.00. introduced in 0.7.11 - DataRelative Angle To Ref (

Angle): "Relative angle to the face reference". Default:0.00. introduced in 0.7.11 - DataSuppl Angle Ref (

Bool): "Supplementary angle reference". Default:true. introduced in 0.7.11 - Datakfactor (

FloatConstraint): "Location of Neutral Line. Caution: Using ANSI standards, not DIN.".

Default:0,50. K factor (also known as neutral factor) for the bend. Used to calculate bend allowance when unfolding. - Datamax Extend Dist (

Length): "Auto Miter maximum Extend Distance". Default:5,00 mm. - Datamin Gap (

Length): "Auto Miter Minimum Gap". Default:0,20 mm. - Datamin Relief Gap (

Length): "Minimum Gap to Relief Cut". Default:1,00 mm. - Dataoffset (

Distance): "Offset Bend". Default:0,00 mm. - Dataunfold (

Bool): "Shows Unfold View of Current Bend". Default:false

trueunfolds the bend.

Parameters Ex2

- DataSketch (

Link): "Sketch Object". - Datasketchflip (

Bool): "Flip Sketch Direction". Default:false. - Datasketchinvert (

Bool): "Invert Sketch Start". Default:false.

Parameters Ex3

- DataLength List (

FloatList): "Length of Wall List". Default:[10.00]. - Databend AList (

FloatList): "Bend Angle List". Default:[90.00].

Parameters Miterangle

- Datamiterangle1 (

Angle): "Bend Miter Angle from Left Side". Default angle:0,00°. - Datamiterangle2 (

Angle): "Bend Miter Angle from Right Side". Default angle:0,00°.

Parameters Perforation

- DataNonperforation Max Length (

Length): "Non-Perforation Max Length". Default:5 mm. - DataPerforate (

Bool): "Enable perforation". Default:false. - DataPerforation Angle (

Angle): "Perforation Angle". Default:0 °. - DataPerforation initial Length (

Length): "Initial Perforation Length". Default:5 mm. - DataPerforation Max Length (

Length): "Perforation Max Length". Default:5 mm.

Parameters Relief

- DataRelief Factor (

Float): "Relief Factor". Default:0,70. - DataUse Relief Factor (

Bool): "Use Relief Factor". Default:false. - Datarelief Type (

Enumeration): "Relief Type".Rectangle(default),Round. Enabled only when a gap value is set. - Datareliefd (

Length): "Relief Depth". Default:1,00 mm. Enabled only when a gap value is set. - Datareliefw (

Length): "Relief Width". Default:0,80 mm. Enabled only when a gap value is set.

Example

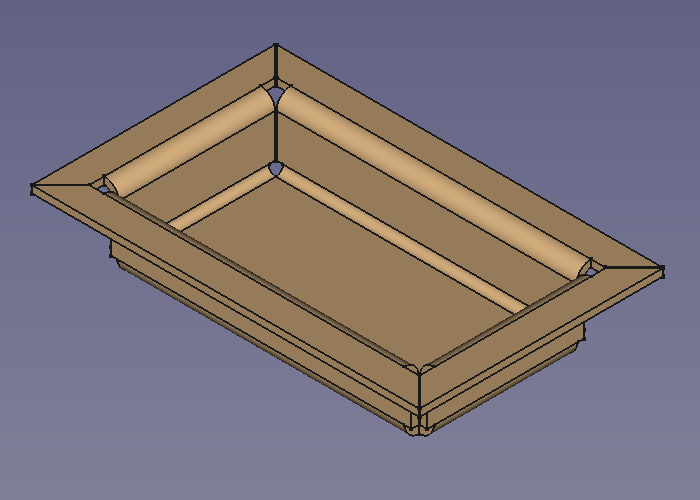

A simple tray

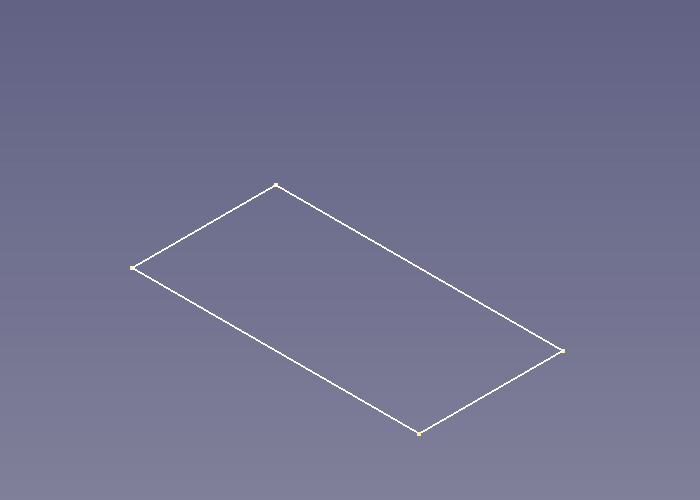

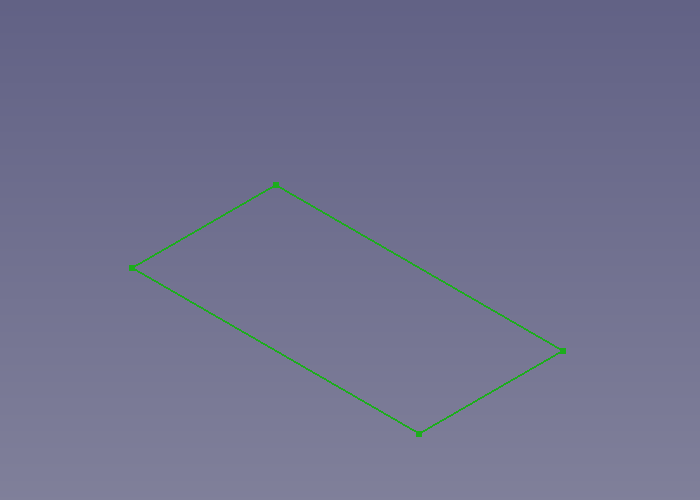

Preparation

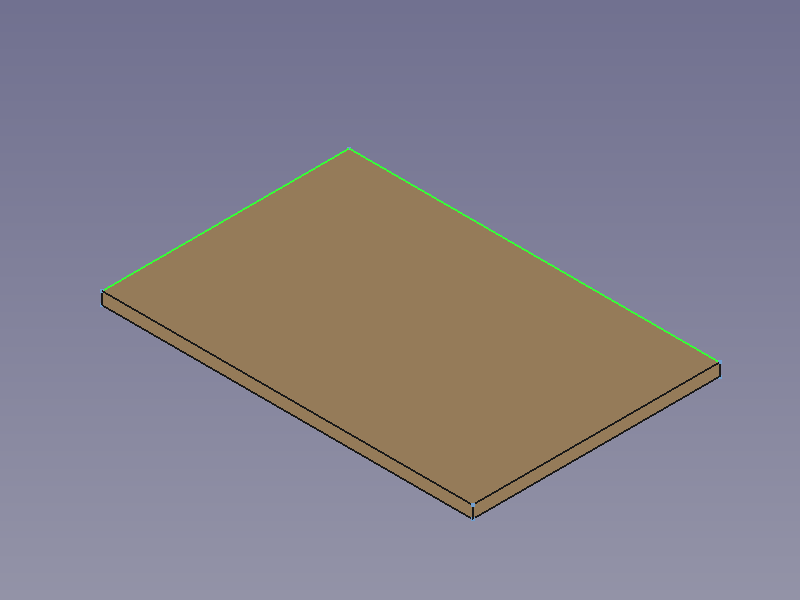

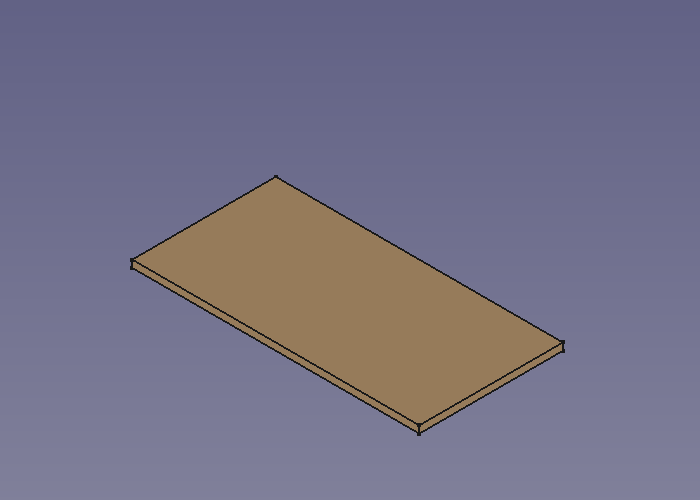

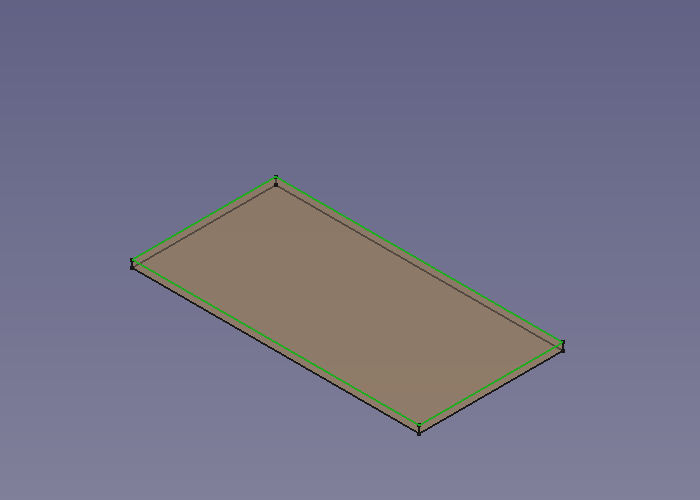

This tray is made of a rectangular blank with walls added to its outline edges. And so one outline sketch for the blank has to be prepared in advance.

Just a rectangular outline

Workflow

- Create a blank

- Select the outline sketch

- Press the

Make Base Wall button

or use the keyboard shortcut: C then F

(The blank is padded in z direction

- Select the outline sketch

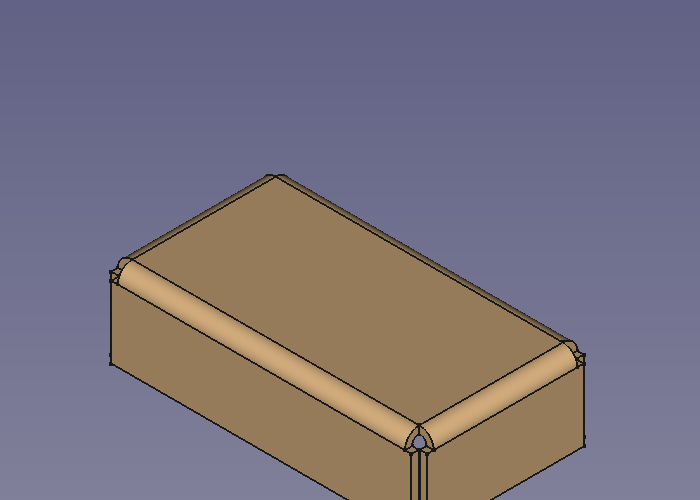

- Add walls to the outline edges

- Select the blank's outline edges

- Press the

Make Wall button

or use the keyboard shortcut: W

- If the fold is 90° down set the value of invert property to true to reverse the direction (and length to a lower value for smaller walls)

- Select the blank's outline edges

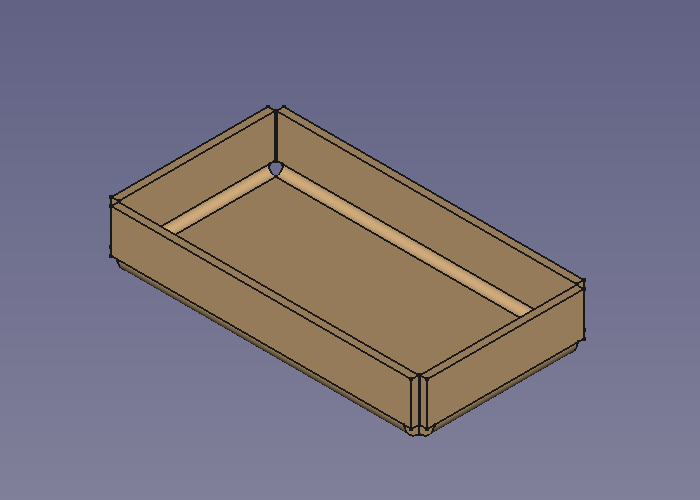

- Add some more walls

- Select the tray's upper outside edges

- Press the

Make Wall button

or use the keyboard shortcut: W

- The walls are a bit too long (but nicely trimmed) and so the length property has to be set to a lower value

- If you like the folds swing outward set the invert value to true

- Select the tray's upper outside edges

Done!