Part Extrude/es

|

|

| Ubicación en el Menú |

|---|

| Pieza → Extrusión |

| Entornos de trabajo |

| Pieza |

| Atajo de teclado por defecto |

| Ninguno |

| Introducido en versión |

| - |

| Ver también |

| Draft Trimex |

Description

Descripción

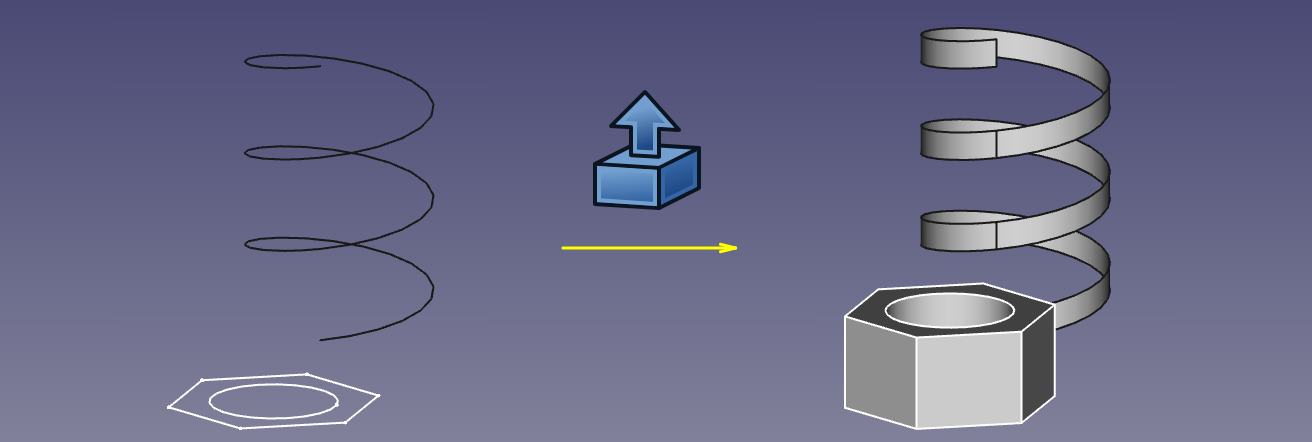

Pieza Extruye extiende una forma por una distancia determinada, en una dirección determinada. El tipo de forma de salida variará dependiendo del tipo de forma de entrada y de las opciones seleccionadas.

In most common scenarios, the following lists the expected output shape type from a given input shape type,

- Extruding a Vertex (point) will produce a straight Edge (Line)

- Extruding an open edge (e.g. line, arc) will produce an open face (e.g. plane)

- Extruding a closed edge (e.g. circle) will optionally produce a closed face (e.g. an open-ended cylinder) or if the parameter "solid" is "true" will produce a solid (e.g. a closed solid cylinder)

- Extruding an open Wire (e.g. a Draft Wire) will produce an open shell (several joined faces)

- Extruding a closed Wire (e.g. a Draft Wire) will optionally produce a shell (several joined faces) or if the parameter "solid" is "true" will produce a solid

- Extruding a face (e.g. plane) will produce a solid (e.g. Cuboid)

- Extruding a

Draft ShapeString will produce a compound of solids (the string is a compound of the letters which are each a solid)

- Extruding a shell of faces will produce a Compsolid.

Examples of extrusion

Usage

- Optionally select one or more shapes in the 3D View or in the Tree View.

- There are several ways to invoke the command:

- Press the

Extrude button.

- Select the Part →

Extrude option from the menu.

- Press the

- The Extrude task panel opens.

- Optionally click on an item in the Shape list to (re-) select a shape.

- Optionally keep Shift pressed and click on an item in the Shape list to either add the shape to the selection, or to remove it from the selection.

- Set the direction and length and optionally other parameters (see Properties for more details).

- Press OK to close the task panel.

- One Extrude object will be created for each selected shape.

Each input shape is placed underneath its Extrude object.

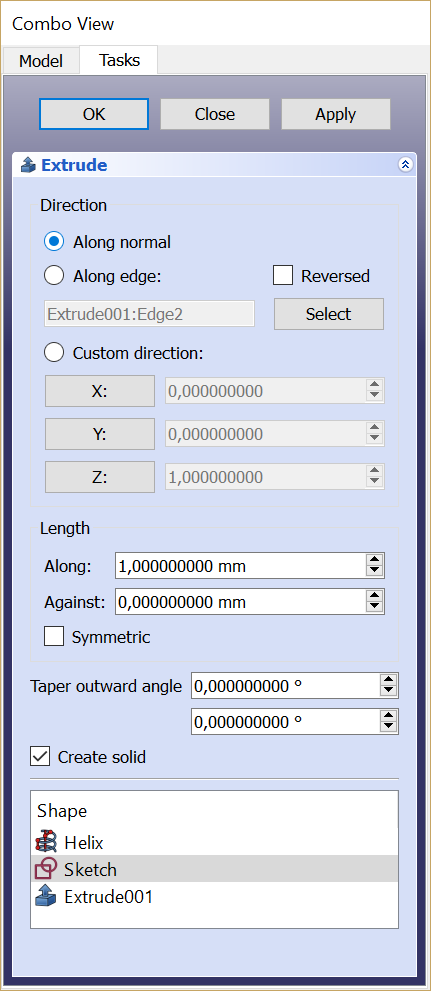

Task panel

- OK button creates the extrusion, and closes the panel.

- Close button closes the panel, without doing anything.

- Apply button creates the extrusion, but does not close the panel. You can then select another shape from the list at the bottom and create more extrusions.

- Direction radio buttons: sets the way the extrusion direction is computed.

- Reversed checkbox: reverses the extrusion direction.

- Select button: click it, and then pick an edge in the 3D View. That edge will appear in text field next to the button, in the format "ObjectName:EdgeN". You can also type the link manually or erase it. The values X, Y, Z will be filled according to the edge direction.

- X, Y, Z buttons: Click a button to set extrusion direction to the positive axis. Click it again to set it to the negative axis.

- X, Y, Z input fields: set or display the direction vector of extrusion. If both lengths are zero, the length of this vector sets the length of extrusion, and values are always in mm, regardless of unit preferences.

- Length fields: set the length of the extrusion. These input fields have unit support.

- Symmetric: spreads out the extrusion into both directions, so that the profile remains in the middle.

- Taper angle along: draft angle for the along direction. Positive angle means profile is expanded at other end of extrusion.

- Taper angle against: idem for the against direction.

- Create solid checkbox: if checked, extruding a closed wire or edge will yield a solid. It is checked by default, if a closed wire was preselected before invoking Part Extrude.

- Shape list: here you select which shapes to extrude. If multiple objects are selected, multiple Extrude objects are created.

Notes

- The task panel does not offer a preview, yet. Apply will create an extrusion object every time you click it, which can be useful as preview; however, they will remain and yet another one will be created as you click OK. Undo can be useful to clean them up before clicking OK.

Comparison with PartDesign Pad

PartDesign Pad is also an extrusion feature, but there are important differences:

- Part Extrude always creates a standalone shape. PartDesign Pad fuses the extrusion result to the rest of the Body.

- Part Extrude can be placed anywhere in the model tree. PartDesign Pad can only be placed inside a PartDesign Body.

- Part Extrude can extrude any object that has a Part geometry (OpenCASCADE shape), except for solids and CompSolids.

- Part Extrude can extrude individual faces of other objects. PartDesign Pad will only accept either Sketch or faces of PartDesign objects as a profile.

Properties

See also: Property View.

A Part Extude object is derived from a Part Feature object and inherits all its properties. It also has the following additional properties:

Data

Extrude

- DatosBase (

Link): The shape to extrude. - DatosDir (

Vector): The extrusion direction. If DatosDir Mode isCustomyou can edit this property, otherwise it is read-only. - DatosDir Mode (

Enumeration): Sets how DatosDir is controlled.Custommeans DatosDir is editable.Edgemeans DatosDir is obtained from an edge (line) linked by DatosDir Link.Normalmeans DatosDir is perpendicular to the plane of the input shape. - DatosDir Link (

LinkSub): Parametric link to an edge (line) that sets the extrusion direction. - DatosLength Fwd (

Distance): Length of extrusion along direction. If both DatosLength Fwd and DatosLength Rev are zero, the length of the DatosDir vector is used. - DatosLength Rev (

Distance): Length of additional extrusion, against direction. - DatosSolid (

Bool): If true, extruding a closed edge or a closed wire will yield a solid. If False, a shell will result. - DatosReversed (

Bool): Reverses the extrusion direction. - DatosSymmetric (

Bool): If true, extrusion is centered at the input shape, and the total length is DatosLength Fwd. DatosLength Rev is ignored. - DatosTaper Angle (

Angle): Applies an angle to the extrusion, so that sides of the extrusion are drafted by the specified angle. Positive angle means the cross-section expands. Inner structures receive the opposite taper angle. This is done to facilitate the design of molds and molded parts. - DatosTaper Angle Rev (

Angle): Sets the taper for the reversed part of the extrusion (the part from DatosLength Rev). - Datos (Hidden)Face Maker Class (

String): Superseded by DatosFace Make Mode (read-only). - DatosFace Make Mode (

Enumeration): If DatosSolid is true, the facemaker class to use when converting wires to faces, otherwise ignored. The options areSimple,Cheese,ExtrusionandBullseye(default).

- Primitives: Box, Cylinder, Sphere, Cone, Torus, Tube, Create primitives, Shape builder

- Creation and modification: Create sketch, Extrude, Revolve, Mirror, Scale, Fillet, Chamfer, Make face from wires, Ruled Surface, Loft, Sweep, Section, Cross sections, 3D Offset, 2D Offset, Thickness, Projection on surface, Color per face

- Boolean: Make compound, Explode compound, Compound Filter, Boolean, Cut, Union, Intersection, Connect objects, Embed object, Cutout for object, Boolean fragments, Slice apart, Slice to compound, Boolean XOR, Check geometry, Defeaturing

- Other tools: Import CAD file, Export CAD file, Box selection, Create shape from mesh, Create points object from geometry, Convert to solid, Reverse shapes, Create simple copy, Create transformed copy, Create shape element copy, Refine shape, Set tolerance, Persistent section cut, Attachment…

- Preferences: Preferences, Fine tuning

- Getting started

- Installation: Download, Windows, Linux, Mac, Additional components, Docker, AppImage, Ubuntu Snap

- Basics: About FreeCAD, Interface, Mouse navigation, Selection methods, Object name, Preferences, Workbenches, Document structure, Properties, Help FreeCAD, Donate

- Help: Tutorials, Video tutorials

- Workbenches: Std Base, Assembly, BIM, CAM, Draft, FEM, Inspection, Material, Mesh, OpenSCAD, Part, PartDesign, Points, Reverse Engineering, Robot, Sketcher, Spreadsheet, Surface, TechDraw, Test Framework

- Hubs: User hub, Power users hub, Developer hub